|

Layout Guidelines |

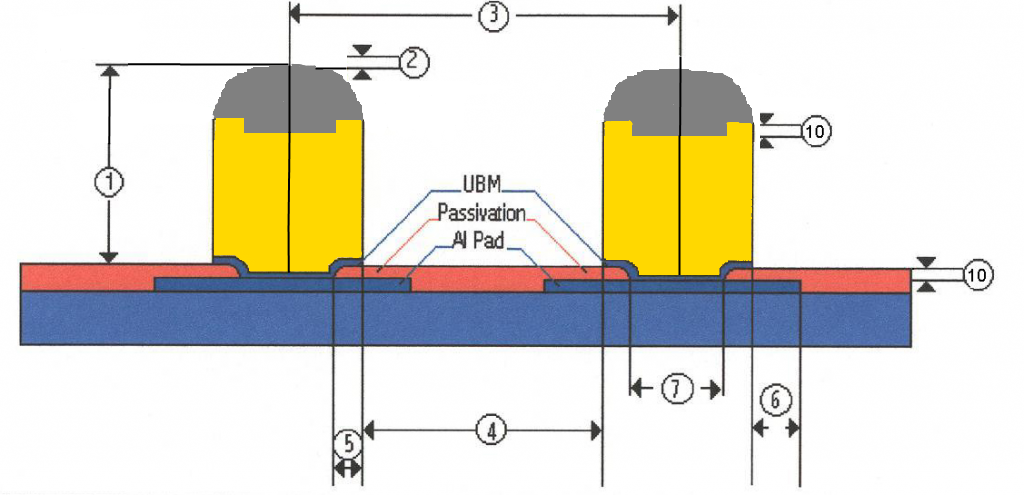

Copper Bumps (Solder, Nickel, Gold or Indium Cap) |

|

|

1 |

Bump Height Average | 100 um (10 um to 250 um stacked available) |

|

2 |

Bump Height Uniformity | ±5% (in die); ±15% (in wafer); ±20% (wfr to wfr) |

|

3 |

Bump Pitch | 150 um Standard (Bump Height Dependence) |

|

4 |

Bump Spacing | 75 µm Minimum (Bump Height Dependence) |

|

5 |

Bump to Passivation Overlap | 8 µm Per Side Minimum (10 um preferred) |

|

6 |

Pad to Bump Overlap | 7 µm Per Side Minimum |

|

7 |

Passivation Opening | 5 µm Minimum (Bump size dependence) |

|

8 |

Cap Height | 2-50um (Before Reflow) |

|

9 |

Passivation Angle of Slope | > 60 Degrees |

|

10 |

Passivation Type | Nitride, OxyNitride, Polyimide |

|

11 |

Passivation Height | 0.5-1.8 um |

|

12 |

Wafer Edge Exclusion Zone | 3 mm |

|

13 |

Mask Layout and Procurement | Requires GDSII or ACAD, Stepping Distance Wafer Map |

|

Specifications |

Copper Bumps (Solder, Nickel, Gold or Indium Cap) |

|

|

1 |

Bump Height Average | 100 um (10 um to 250 um stacked available) |

|

2 |

Copper Shear Strength Height | >12 grams/mil2 |

|

3 |

Voids | <10% of Solder Bump Volume, No Exposed Pad |

|

4 |

Missing Bumps | None Outside Exclusion Area |

Copper Bumping